Imagine a material that not only mimics the flexibility of muscle but also repairs itself under stress, becoming stronger with each challenge. Researchers at WPI-ICReDD have taken a significant step toward this reality with a new “recipe” for a self-strengthening hydrogel. This isn’t just an incremental improvement; it’s a fundamental shift in how we design and utilize these versatile materials.

Hydrogels, known for their unique blend of water and polymer networks, are already used in a wide array of applications, from contact lenses to drug delivery systems. The key to this innovation lies in the strategic integration of computational modeling, data analysis, and experimental validation. This approach allowed the researchers to identify and incorporate specific molecular components, called mechanophores, that trigger rapid self-reinforcement when the gel is subjected to mechanical stress.

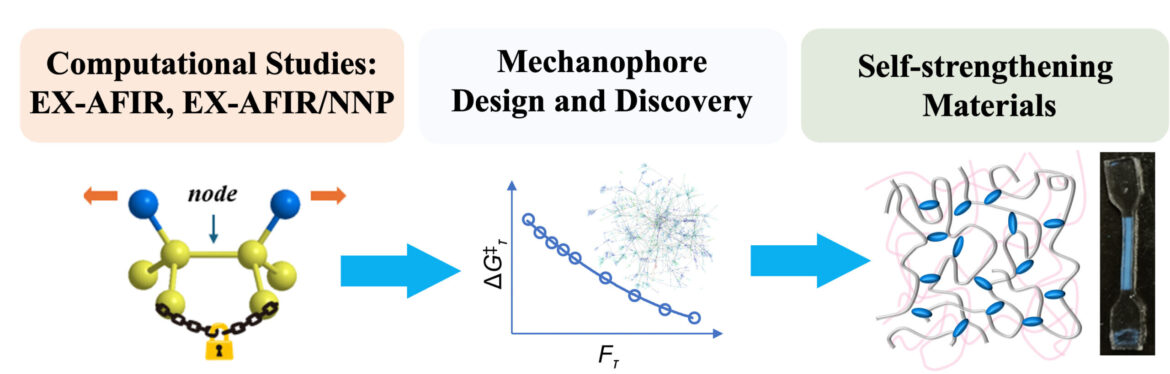

Professor Gong’s group has a history of groundbreaking work in double-network hydrogels. Their previous research demonstrated that mechanical stress could induce self-strengthening by breaking brittle polymer networks and generating radicals. These radicals, in turn, would react with monomers within the material, creating new, stronger polymer networks.

The latest breakthrough hinges on incorporating mechanophores with specially designed weak bonds into the brittle network. These weak bonds, when broken under stress, dramatically enhance the efficiency of radical generation, leading to significantly faster self-strengthening. However, these same weak bonds pose a challenge: they are also susceptible to heat and light, which could compromise the material’s overall stability. The research team needed to find a way to maximize force-sensitivity while maintaining robust stability.

Debate Overview

The development of self-strengthening hydrogels involves navigating several challenges. The central debate revolves around maximizing the material’s responsiveness to mechanical stress while ensuring its long-term stability and versatility. The research team had to address key questions to produce a hydrogel fit for purpose.

- How to engineer mechanophores that are both sensitive to force and resistant to environmental factors like heat and light?

- What computational methods can accelerate the design and testing of these complex materials?

- How can the self-strengthening mechanism be optimized for various applications, from biomedical implants to soft robotics?

Key Arguments

The team at WPI-ICReDD addressed these challenges by integrating computational design with experimental validation. Professor Maeda’s group developed the Artificial Force Induced Reaction (AFIR) method, which automatically explores reaction pathways. Associate Professor Jiang extended this with the EX-AFIR method, which predicts the force needed to break polymer chains under mechanical stress. By combining EX-AFIR with machine learning, Assistant Professor Staub and Professor Varnek were able to rapidly screen mechanophore candidates and identify crucial molecular parameters. They predicted that limiting rotation within a polymer chain would create “nodes” where the chain would break under weak force, even with strong bonds.

“This computational design allowed us to rapidly evaluate a vast number of mechanophore candidates, something that would have been impossible with traditional experimental methods alone,” explains Professor Maeda.

Gels synthesized from these selected mechanophores exhibited rapid reinforcement and remained stable after exposure to heat (80°C) and UV light for 10 hours. This confirmed the importance of the node-like structure. Conversely, gels made from computationally rejected mechanophores failed to demonstrate self-strengthening, validating the computational design approach.

The video illustrates the radical generation of various hydrogels—DN-Cam (suggested by simulations), DN-Cy, and DN-Pin (filtered out by simulations). The DN-Cam gel, as predicted, showed a notable color change, indicating stable radical generation. This visual evidence strongly supports the computational models’ accuracy.

This integrative approach marks a significant advance in materials science, demonstrating the power of combining computational modeling with experimental validation to accelerate technological progress. The researchers have effectively decoupled the conflicting demands of force-sensitivity and material stability.

One of the researchers, speaking on condition of anonymity, stated, “This is a story we need to tell,” highlighting the potential impact of this research. Online reactions have been largely positive, with many expressing excitement about the possibilities this technology unlocks. A comment on X.com read, “Imagine self-healing implants! The future is here!” while a post on Facebook queried, “Could this be used in better prosthetics?”. However, some concernse were raised about the potential cost and scalability of the manufacturing process. One user on instagram commented, “It’s amazing, but will it be affordable?”

Unresolved Questions

Despite these advancements, several questions remain:

- What are the long-term effects of repeated stress-induced strengthening on the hydrogel’s performance?

- How can the self-strengthening mechanism be tailored for different types of mechanical stress (e.g., compression, tension, shear)?

- Can this approach be extended to other types of materials beyond hydrogels?

The team’s findings, published in Chemical Science, offer exciting opportunities for applications ranging from biomedical implants with enhanced durability to soft robotics capable of withstanding harsh conditions. Further research will undoubtedly focus on fine-tuning the material’s properties and expanding its range of potential applications.

The implications of a muscle-like gel polymer that grows stronger with use are profound. It’s not just about creating more resilient materials; it’s about paving the way for a future where technology adapts and evolves with the challenges it faces. This inovation of combining computational analysis with material science will make building more resiliant structures more efficient.

More information: Julong Jiang et al, “Node” facilitated thermostable mechanophores for rapid self-strengthening in double network materials, Chemical Science (2025). DOI: 10.1039/D5SC00151J

Provided by Hokkaido University